Just a few of the term used in this blog and short description of what is meant by it.

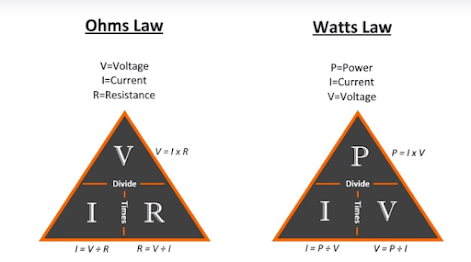

Ohms law is the relationship between Voltage Volt, Current Amps and Resistance OHM.

Voltage, current and resistance.

Voltage is the power of the supply and can be 6v 12v or even 230v in a home.

Current is the measurement of the amount of electricity a load is taking the larger the load the larger the current and also the larger the wiring needs to be , Amps and be AC alternating or DC direct current, Usually 230v AC in domestic homes.

Resistance is any restriction the electricity current has to face when travelling through the circuit and can be the wire and connection or terminal and the load itself will have a determined resistance than can be measured in Ohms.

Hertz , the way a generator works it will create AC alternating current this means it reverse direction of current, the amount of cycles per second between Positive and Negative is know as hertz in the UK its set a 50hz or 50 cycles per second.

Power Is a measure of the electrical energy used by a component measured in watts. 100 watt light bulb, 1800w or 1.8Kw element.

You need to know a little about these in order to understand how to fault find, its best to watch youtube videos and animations to understand this but its all relatively straight forward.

Use the triangle to calculate any of the needed value divide blow into top and Multiply the lower.

Here is an example - The resistance of a heater element is 20 ohms the measure voltage and UK domestic voltage is 230v to find current devide 230 / 20 = 11.5 Amps.

In more modern appliances a PCB, Relays and sensors do the job of many of the selector switches, This enables very precise and economic control of the heating saving energy and giving better user experience.

Some of the less expensive parts can be easily tested and replaced on PCBs but the more complex chips are not so easy to test find or replace and sometime its better to replace the PCB or it might be more cost effective to buy a replacement cooker oven depending on age of machine.

Some even give error codes it an attempt to help the engineer fault find but if the PCB is dead then this is not possible if you get error codes you will need manufacturer information to find the codes and solutions.

Common issues

PCB have many components and these can fail over time , it is possible for a failure in an oven component for example a shorted element or sensor to destroy board components so bare this in mind when doing your diagnostics on the machine.

A general rule is that if after testing all other components and eliminating them from diagnosis , and they all test good, then you can assume the PCB is faulty, this is an expensive call so you need to be sure.

Normally i would not test board i would test incoming cables and thermal cut out device then switches . But sometimes you can see the relay faulty or a damaged capacitor may a potentiometer has failed if on the board.

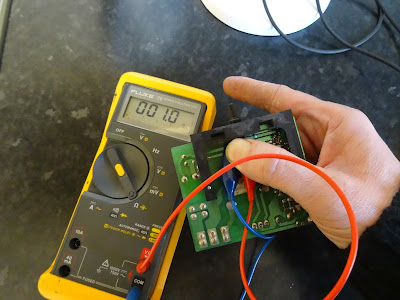

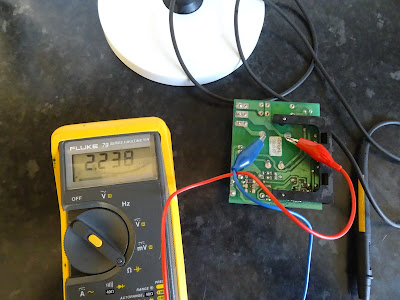

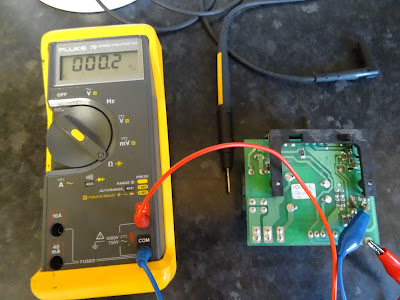

But for this study ill take board out and have a good look over it.

some example boards from electric showers

Sensor are use to give the PCB accurate temperature measurements of the oven cavity to ensure precise cooking , these are usually NTC type temp sensors

There are other methods to regulate the temperature but the most used today is the NTC sensor, the NTC sensor is a semi conductor and as the temperature in the oven cavity rises the resistance through the sensor decreases which is then used to control the on / off time cycling of the heating element.

NTC sensors monitor the cavity temperature and use this information to calculate if the heating time should be increased or decreased.

To test the sensor you need to set multimeter to ohms and check measurements against manufacturer documents.

Its best to test the ntc at room temperature and measure against known good values but its possible to use hot water to test at a range of temperatures.

Common issues

NTC can fail open circuit as well so will test OL on the multimeter so test for this , it may also trigger an error message depending on age and make - model.

if they test OL or out of specification then replace them

.JPG)

No comments:

Post a Comment